Introduction

As the landscape of industrial automation continually evolves, Opto 22 emerges as a leader, especially with its pivotal CCANI (Controller Area Network Integration) technology. This advanced solution redefines communication frameworks within various sectors by offering superior capabilities compared to traditional CAN systems. CCANI, particularly through the GRV-CCANI-2 Serial Module, significantly enhances data transmission across networks, ensuring more efficient, reliable, and scalable operations. Opto 22’s integration of CCANI not only facilitates robust network solutions but also supports complex Edge Processing in Automation, making it an essential component of Industrial IoT Solutions. These innovations are tailored to meet the high demands of modern industries, positioning Opto 22’s industrial solutions at the cutting edge of technological advancement in automation.

About CCANI

CCANI, or Controller Area Network Integration, redefines the standards set by traditional CAN protocols, bringing enhanced capabilities to industrial networks. Initially designed for automotive applications, CCANI now thrives within the realm of industrial automation. This sophisticated system offers a robust and flexible network solution adept at navigating the complex demands of contemporary industrial environments.

Leveraging its roots in traditional CAN technology, CCANI introduces a suite of advanced features. These include higher data rates, improved error handling, and fortified security measures, which are pivotal for modern industrial systems. Such enhancements ensure dependable and real-time communication across multiple devices, crucial for operational consistency and efficiency in automation processes.

Opto 22 and CCANI Integration

At the forefront of industrial automation, Opto 22 continues to innovate with the integration of Controller Area Network Integration (CCANI) technologies into their robust product lineup. The adoption of CCANI enhances communication protocols across systems, heralding a new era of connectivity and control within the industry. This integration not only simplifies the infrastructure but also boosts efficiency and scalability, making Opto 22’s solutions more adaptable to the diverse needs of modern industrial environments.

Introducing GRV-CCANI-2:

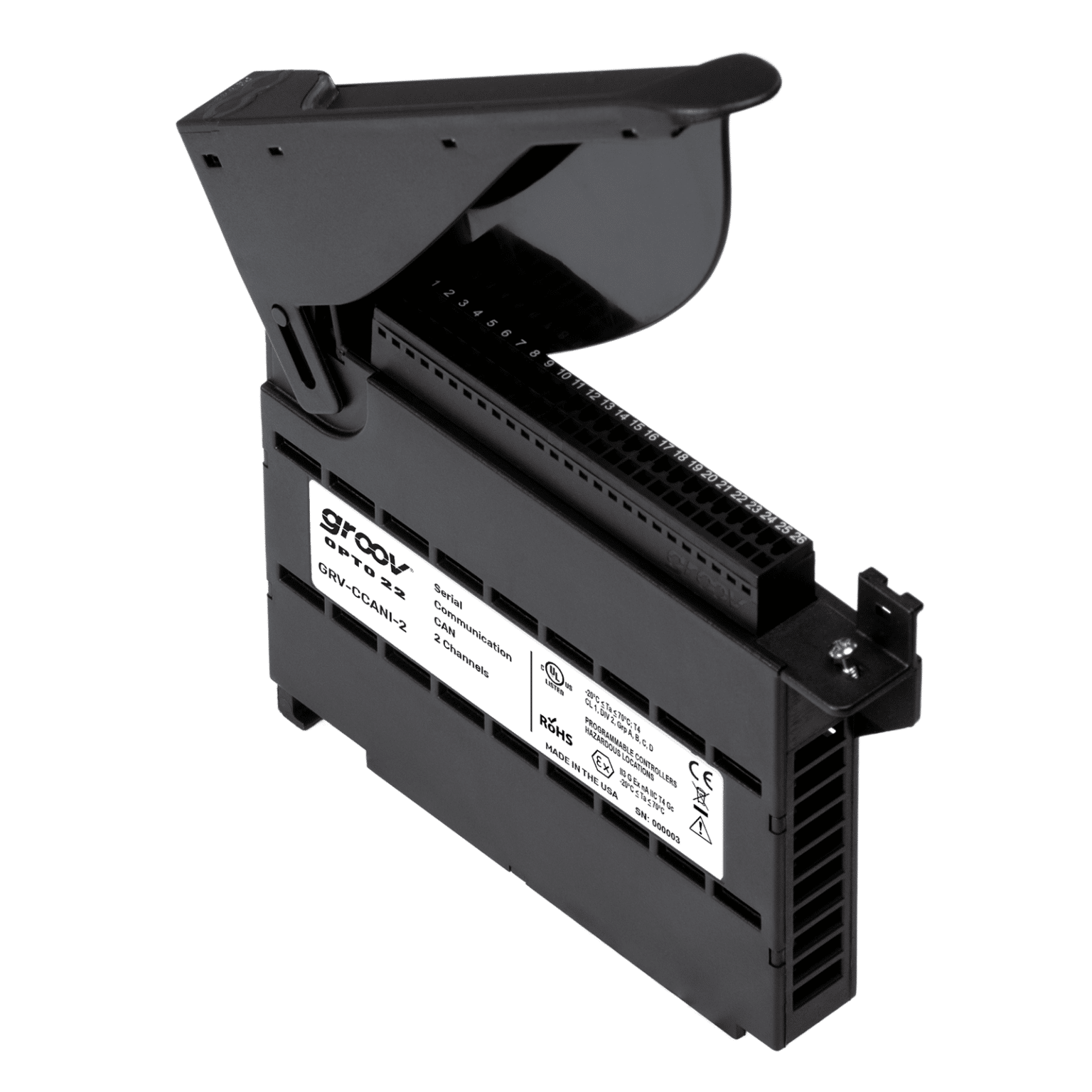

Opto 22’s commitment to advancing industrial communication is exemplified by the GRV-CCANI-2 serial module, a standout addition that provides dual independent, isolated serial channels, enabling the GRV-EPIC-PR1 to communicate through a Controller Area Network (CAN). Mounted on any groov EPIC chassis, this module works alongside a GRV-EPIC-PR1 processor and various analog and discrete groov I/O modules to deliver the precise mix of signals needed at any location. These modules are directly connected to the processor via the bus on the chassis, acting as ports built into the processor and can be installed in any of the first four positions on the chassis.

The groov RIO, another integral part of Opto 22’s offerings, supports CCANI as well, providing enhanced flexibility and ease for remote I/O applications. The groov RIO’s modular design and built-in I/O channels facilitate seamless communication with a broad array of devices across industrial setups, positioning it as an ideal companion for CCANI-enabled systems. Leveraging both groov EPIC and groov RIO’s capabilities ensures that industrial operations achieve unmatched efficiency and reliability.

5 Benefits of CCANI in Industrial Automation:

- Versatile Connections: CCANI enables seamless integration with a diverse range of sensors and devices throughout your facilities. This versatility ensures smooth data flow and integration across various components of your industrial setup, enhancing overall system performance.

- Edge Processing: With CCANI, you can experience faster response times and increased reliability by reducing reliance on cloud services. This edge processing capability is crucial for real-time operations where every millisecond counts, making your industrial processes more responsive and efficient.

- Robust Security: In today’s digital age, safeguarding your data is more critical than ever. CCANI employs top-notch encryption and authentication protocols, ensuring that your industrial networks are protected against cyber threats and unauthorised access

- Expandable I/O: One of the standout features of CCANI is its ability to grow with your needs. Opto 22’s modular design allows you to easily expand your system’s capabilities by adding new I/O modules as required, making CCANI an ideal choice for scalable industrial environments.

- Superior Data Handling: Efficient data management capabilities are at the core of CCANI’s design. By enabling the handling of large volumes of information with minimal risk of errors, CCANI optimises overall system performance, ensuring that your industrial operations run smoothly and efficiently.

Implementation Strategies and Challenges of CCANI

As we embrace the next step in industrial automation, the integration of CCANI technology offers transformative prospects but also presents unique challenges. These range from ensuring compatibility with existing systems to the necessity for skilled personnel capable of managing the transition effectively. At Opto 22, we are committed to turning these potential obstacles into opportunities for growth and advancement.

Comprehensive Support and Training:

Recognising the complexities involved in CCANI integration, we provide extensive support and progressive training aimed at equipping businesses with the necessary tools for a seamless transition. This approach is not merely about upgrading technology but also about instilling confidence and peace of mind as your business steps into the future of industrial automation.

- Detailed Implementation Guides: To simplify the adoption process, we offer thorough guides and documentation. These resources are designed to clarify setup procedures and operational guidelines, ensuring a smooth transition.

- Expert Customer Support: Access to experienced engineers is crucial for addressing specific challenges that may arise during integration. Our customer support is structured to provide real-time solutions and hands-on assistance, making the integration process as smooth as possible.

- Advanced Planning Tools: We also provide sophisticated tools that help businesses anticipate and plan for integration scenarios. These tools are aimed at minimising risks and optimising the deployment strategy to ensure success from the start.

By leaning on our robust support network, your business can confidently address the complexities of adopting advanced technologies. This strategic support not only mitigates risks but also enhances the reliability and efficiency of operations, laying a strong foundation for future innovations in industrial automation.

Technical Guidance on CCANI

As we advance into the future of industrial automation, setting up a CCANI network is a critical endeavor that requires meticulous planning and execution. Here’s a detailed guide to ensuring your CCANI setup not only meets but exceeds industry standards.

Planning the Network Layout:

- Integration Points Identification: The first step involves a detailed analysis of your existing infrastructure to identify crucial integration points. This stage is pivotal as it determines how CCANI will interface with your current systems, ensuring optimal performance.

- Strategic Layout Planning: Using the insights from the initial analysis, we plan the physical and logical layout of the network. This involves mapping out the exact locations of devices, sensors, and controllers and designing the most effective paths for data transmission.

Installing CCANI-Enabled Devices:

- Precision Installation: Installing CCANI-enabled devices is not just about physical setup but ensuring that each component communicates seamlessly with the rest of the system. This process requires a high level of precision, and our team is equipped to handle these needs with utmost accuracy.

- Configuration for Performance: Each device is carefully configured to meet specific operational demands. This customization is crucial for the network’s overall performance and reliability.

Testing and Optimisation:

- Comprehensive Testing: Once the network is in place, a series of rigorous tests are conducted to assess its stability and performance. This phase is crucial to identify and rectify any potential issues before they affect the network’s operation.

- Continuous Optimization: Post-testing, the network enters a phase of continuous optimization where regular monitoring and maintenance are conducted. This proactive approach ensures that the network remains efficient and reliable, adapting to any operational changes or technological advancements.

By following this structured approach, we can guarantee that your CCANI network will be robust, efficient, and future-ready. Should you require assistance in setting up your own CCANI network or wish to understand how it can enhance your operational efficiency, our engineering team is available to offer expert guidance and support. Please do not hesitate to contact us for professional advice on making a smooth transition to advanced industrial automation.

Conclusion

CCANI by Opto 22 marks a transformative advancement in industrial automation. By integrating this sophisticated network system, industries can significantly boost their operational efficiency and strategically position themselves for the technological evolutions of tomorrow. The synergy between CCANI and Opto 22’s groov EPIC and groov RIO systems cements its role as a pivotal force in industrial automation, equipping businesses with the essential tools for success in an ever-evolving marketplace.

For a deeper understanding of how CCANI can revolutionise your operations, or to discuss your specific needs with an Opto expert, get in touch with us.