Home » groov EPIC vs groov RIO

groov RIO vs groov EPIC: A Comprehensive Comparison for Industrial Automation Solutions

Ivor Houston / SEp 03 2024 / 10 min read

Introduction

In the rapidly evolving world of industrial automation, selecting the right hardware is crucial for ensuring efficient, scalable, and reliable operations. Two of the most advanced products in this domain are the groov RIO and groov EPIC from Opto 22. Both are designed to address specific needs in automation, but their functionalities, use cases, and advantages differ. This article aims to provide a detailed comparison between groov RIO and groov EPIC, helping you decide which solution is the best fit for your industrial automation requirements. As an official authorised distributor of Opto 22 products in Australia, Binford Tech is here to guide you through your decision-making process.

Overview of groov RIO and groov EPIC

Before diving into the comparison, it’s important to understand what groov RIO and groov EPIC are and the roles they play in industrial automation.

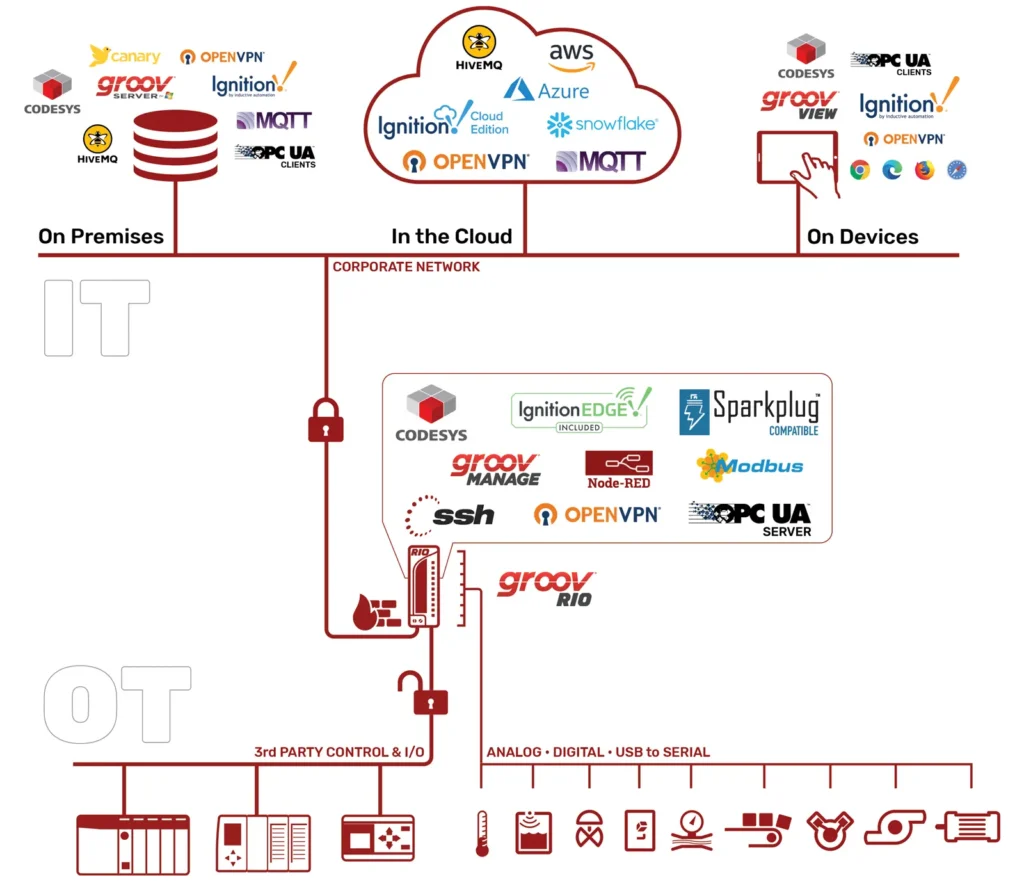

What is groov RIO?

The groov RIO (Remote I/O) is a compact, flexible, and versatile edge I/O module that allows you to connect nearly any industrial sensor or device to Ethernet networks, without the need for complex programming. Designed for simplicity and ease of use, groov RIO is ideal for connecting remote locations, integrating legacy systems, and facilitating IIoT (Industrial Internet of Things) deployments. Click here to visit our groov RIO page for more information.

Key features of groov RIO include:

- Multi-Signal Support: One module can handle a wide variety of I/O signals.

- Edge Processing: Perform data processing at the edge, reducing latency and network load.

- Easy Configuration: No programming required; configure directly via a web browser.

- Scalability: Easily scalable for various applications and system sizes.

groov RIO's Modules:

groov RIO modules are designed to cater to a variety of industrial applications, with three distinct types available to meet different needs. Below is a breakdown of these key groov RIO modules, highlighting their features and ideal use cases:

1. groov RIO MM1 (GRV-R7-MM1001-10):

- Features: Remote Universal I/O with 8 software-configurable channels and 2 form C electromechanical relay output channels.

- Use Case: Ideal for general-purpose remote I/O applications requiring versatile and easy-to-use I/O capabilities.

2. groov RIO MM2 (GRV-R7-MM2001-10):

- Features: Remote Universal I/O with 8 software-configurable channels, 2 form C electromechanical relay output channels, and Ignition Edge 8 pre-installed.

- Use Case: Suitable for more advanced applications that require enhanced data processing and integration capabilities provided by Ignition Edge 8.

3. groov RIO EMU (GRV-R7-I1VAPM-3):

- Features: 3-phase power and energy monitoring, providing 18 data and accumulation values per phase, along with 10 summation values.

- Use Case: Perfect for energy monitoring and management in industrial settings, offering precise and comprehensive power data.

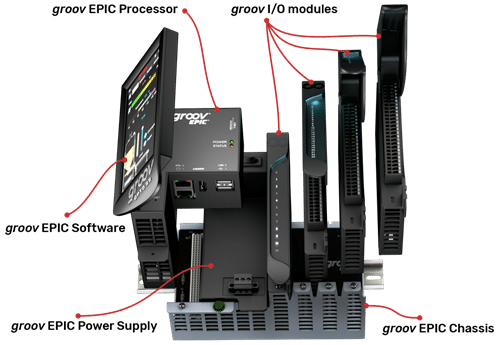

What is groov EPIC?

The groov EPIC (Edge Programmable Industrial Controller) is a comprehensive industrial controller that combines the functionality of a PLC (Programmable Logic Controller), HMI (Human-Machine Interface), and edge computing into a single unit. EPIC is designed for advanced automation tasks, integrating control, visualisation, and data processing on the edge.

Key features of groov EPIC include:

- Integrated Control and Visualization: Combines PLC functions with built-in HMI capabilities.

- Modular Design: Allows for customization and expansion with different I/O modules.

- Edge Computing: Enables real-time data processing and analytics on the edge.

- Open Platform: Supports multiple programming languages and protocols, ensuring flexibility and future-proofing.

Two types of groov EPIC Processors:

The groov EPIC processors are the heart of your industrial automation system, providing the control and processing power needed for complex applications. There are two main types of groov EPIC processors, each designed to meet different levels of performance requirements:

GRV-EPIC-PR1 (groov EPIC PR1):

- Features: Programmable automation controller with Ignition 7 pre-installed.

- Use Case: Ideal for standard industrial automation tasks that require robust control and visualization capabilities. The PR1 is perfect for applications where the existing features and performance of Ignition 7 meet the operational needs.

GRV-EPIC-PR2 (groov EPIC PR2):

- Features: Programmable automation controller with increased RAM & storage, and Ignition 8 pre-installed.

- Use Case: Best suited for more demanding industrial applications that require enhanced performance. The PR2’s additional RAM and storage make it ideal for environments where more intensive processing and larger data storage are needed, particularly when leveraging the advanced features of Ignition 8.

groov RIO vs groov EPIC: Key Differences

While both groov RIO and groov EPIC are designed to enhance industrial automation, they serve different purposes and are suited for different applications. Below, we break down the key differences to help you make an informed decision.

Purpose and Application

groov RIO:

- Ideal for distributed I/O needs, remote monitoring, and IIoT applications. groov RIO excels in situations where you need to quickly and easily connect sensors and devices to a network without the need for complex infrastructure.

- Use cases include integrating legacy systems, adding remote sensors, or connecting disparate systems across multiple locations.

groov EPIC:

- Best suited for comprehensive control and automation tasks. EPIC integrates control, HMI, and edge computing, making it ideal for complex automation environments where you need to manage, monitor, and process data from multiple sources in real-time.

- Use cases include full-scale automation projects, complex process control, and environments where data analytics and edge processing are critical.

Hardware and Design

groov RIO:

- Compact and modular design with up to 8 universal I/O channels per module. Its small footprint makes it ideal for installations in tight spaces or retrofitting into existing systems.

- The design emphasizes flexibility, allowing each channel to be configured for different types of signals.

groov EPIC:

- A robust and expandable design with multiple I/O modules available. EPIC’s modularity allows for customization based on the specific needs of your automation environment.

- The hardware integrates a touchscreen display for local HMI, along with multiple networking ports, making it a powerful tool for complex automation setups.

Programming and Configuration

groov RIO:

- No programming is required for basic setup. Configuration is done through a web browser, making it accessible even for users without extensive programming knowledge.

- groov RIO supports RESTful APIs, MQTT, and other modern protocols, which simplifies integration with other systems and IIoT platforms.

groov EPIC:

- Offers a full-fledged programming environment with support for flowchart-based programming, as well as traditional languages like IEC 61131-3, Python, and Node-RED.

- The built-in HMI can be programmed directly from the device, allowing for seamless integration of control and visualization.

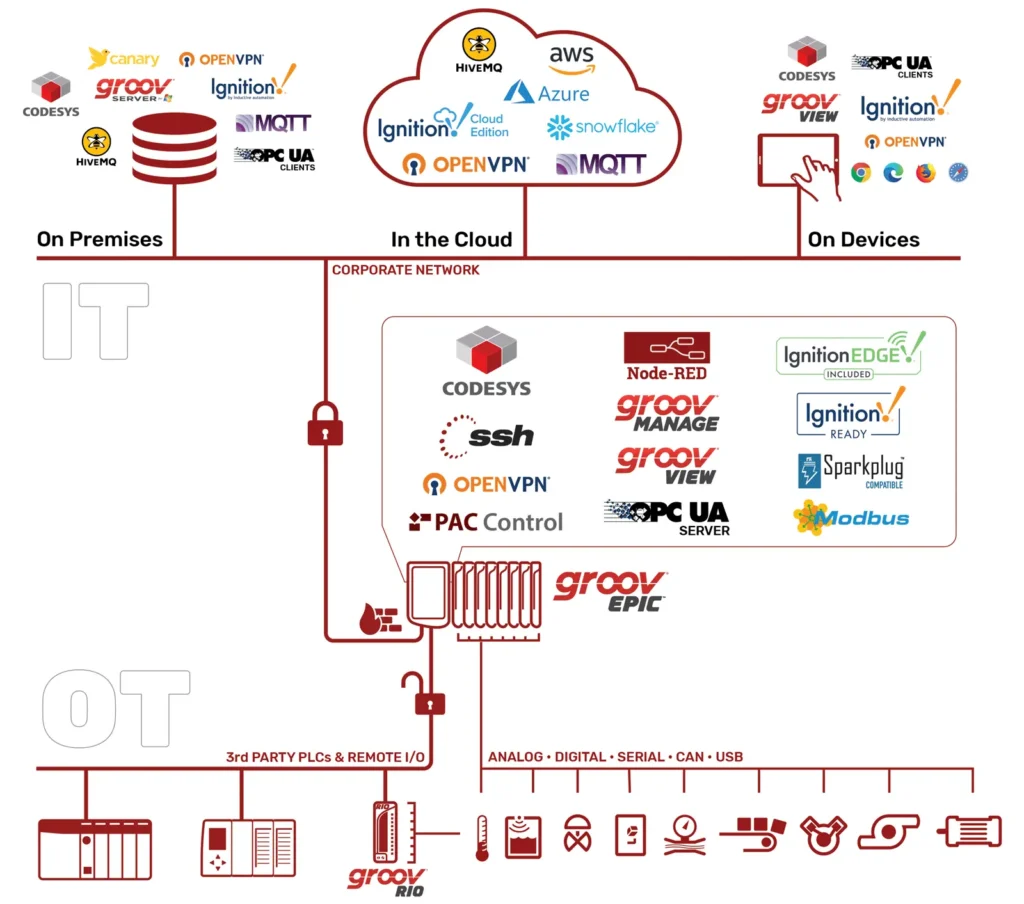

Connectivity and Integration

groov RIO:

- Designed with extensive connectivity options, including Ethernet, MQTT, REST APIs, and OPC UA. This makes it an excellent choice for integrating with cloud platforms and other IT systems.

- RIO’s flexibility allows it to act as a bridge between legacy systems and modern networks, facilitating IIoT deployments.

groov EPIC:

- EPIC’s connectivity options are even more comprehensive, with support for multiple network interfaces, serial communications, and fieldbus protocols. This makes it highly adaptable to various industrial environments.

- EPIC’s integration capabilities extend to IT/OT convergence, enabling seamless data flow between production systems and enterprise-level applications

Cost and Scalability

groov RIO:

- Generally more cost-effective for small to medium-sized projects or when you need to add remote I/O points without investing in a full control system.

- Scalable by adding more RIO modules as needed, making it a flexible solution for growing systems.

groov EPIC:

- Represents a higher initial investment but offers comprehensive functionality, reducing the need for additional hardware and software. EPIC’s scalability and modularity justify the cost in larger, more complex automation projects.

- Its all-in-one nature can lead to long-term cost savings by consolidating control, HMI, and data processing into a single platform.

Software

groov RIO:

- groov Manage: A built-in tool that allows you to configure and manage your groov RIO devices easily via a web browser.

- Node-RED: An open-source programming tool that allows you to wire together devices, APIs, and online services using a visual flow-based programming interface.

- Ignition Edge (Only on MM2): Included with the groov RIO MM2, this software provides limited but powerful HMI and SCADA capabilities, enabling you to collect, store, and visualize data at the edge.

- CODESYS: With the addition of CODESYS (starting from firmware version 3.5), groov RIO can now function as a compact real-time controller. This allows programming in IEC 61131-3 languages, such as Ladder Logic and Structured Text, adding full PLC functionality for industrial control applications.

- MQTT with Sparkplug B: Enables real-time data transmission between edge devices and the cloud, ensuring smooth IIoT integration with Sparkplug B compliance.

- REST API: Allows developers to integrate groov RIO with web-based or cloud applications via RESTful commands.

- Python: Supports Python scripting for custom automation, data manipulation, and extended functionality.

- OPC UA Server: Facilitates secure, platform-independent communication with SCADA systems and industrial equipment through the built-in OPC UA server.

groov EPIC:

- groov Manage, groov View, PAC Control Runtime, and Node-RED: Pre-installed on all groov EPIC processors, these tools provide robust control and automation capabilities out of the box.

- CODESYS® Runtime: A leading platform for industrial automation programming, enabling sophisticated control strategies and programming in IEC 61131-3 languages.

- Ignition Edge®: A powerful tool for edge computing that allows you to collect, store, and visualize data, as well as integrate with broader Ignition SCADA systems. The EPIC PR2 includes Ignition Edge 8 for even more advanced features.

- Secure Shell (SSH): Pre-installed for secure remote management, but requires a license to fully enable.

- MQTT with Sparkplug B: Supports efficient real-time data communication between edge devices and cloud or SCADA systems, enabling IIoT integration.

- OPC UA Server/Client: Facilitates platform-independent, secure communication between groov EPIC and other industrial devices or SCADA platforms.

- REST API: Enables easy integration with custom applications and third-party systems for remote control and data exchange.

- Python and JavaScript (Node.js): Supports custom scripting to create specialized applications for automation and data handling.

- PAC Display™: Allows for the creation of custom HMIs, integrating seamlessly with PAC Control for real-time visualization of industrial processes.

- CAN Bus Support: For communicating with CAN devices in industrial or automotive applications.

- Ignition Full (Optional): Available as an optional license for users requiring full SCADA functionality, with unlimited tags and advanced features for large-scale systems.

Licenses

groov RIO:

Ignition Edge License:

- GROOV-LIC-EDGE8: Required for fully enabling Ignition Edge version 8, which is pre-installed on the groov RIO MM2. This license unlocks additional HMI and SCADA features at the edge, making it ideal for more complex monitoring and control applications.

Secure Shell License:

- GROOV-LIC-SHELL: Required to enable Secure Shell access for remote management of groov RIO systems, ensuring secure communications and control over your remote I/O modules.

groov EPIC:

- GROOV-LIC-CRE: groov EPIC license for CODESYS Runtime, enabling advanced control and automation programming.

- GROOV-LIC-EDGE: groov EPIC license for Ignition Edge version 7, perfect for users leveraging the earlier version of Ignition for their automation needs.

- GROOV-LIC-EDGE8: groov EPIC/RIO license for Ignition Edge version 8, ideal for those who require the latest features and capabilities of Ignition Edge.

- •GROOV-LIC-SHELL: groov EPIC/RIO license for Secure Shell access, ensuring secure and remote management of your EPIC systems.

Choosing the Right Solution for Your Needs

When deciding between groov RIO and groov EPIC, it’s essential to consider the specific needs of your automation project.

Choose groov RIO if:

- You need a flexible, easy-to-deploy solution for remote I/O, sensor integration, or IIoT applications.

- Your project requires quick scalability and integration with existing systems without significant reconfiguration.

Choose groov EPIC if:

- Your project involves complex automation tasks that require integrated control, HMI, and edge computing.

- You need a future-proof, scalable solution that can handle a wide range of industrial protocols and programming environments.

For more information on choosing between groov RIO vs groov EPIC, download Opto 22’s comprehensive comparison guide here.

Conclusion

Choosing the right industrial automation solution is critical to optimizing your operations, and both groov RIO and groov EPIC offer compelling features tailored to different needs. groov RIO excels in providing a flexible, cost-effective solution for distributed I/O, remote monitoring, and IIoT applications. It’s an excellent choice for businesses looking to enhance their existing infrastructure with minimal complexity, especially when integrating legacy systems or deploying simple edge processing tasks.

On the other hand, groov EPIC represents a more comprehensive approach, ideal for complex automation environments that demand robust control, advanced data processing, and extensive customization. With its modular design, multiple processor options, and a wide array of software tools, many of which require specific licenses—groov EPIC is best suited for organisations aiming to future-proof their operations, scale efficiently, and integrate seamlessly with broader enterprise systems.

For expert advice and access to the full range of Opto 22 products, Binford Tech is your trusted partner in Australia. Contact us today to learn more about how groov RIO and groov EPIC can transform your industrial automation strategy.